Category: Chemical industry

Introduction: HS series 3D motion mixer has obtained multiple patentsPatent number: 200620018456.1 200920307169.6 200920307195.9 200920315083.81、 The purpose and characteristics of the equipmentThis machine is a high-efficiency mixing equipment that can be used fo…

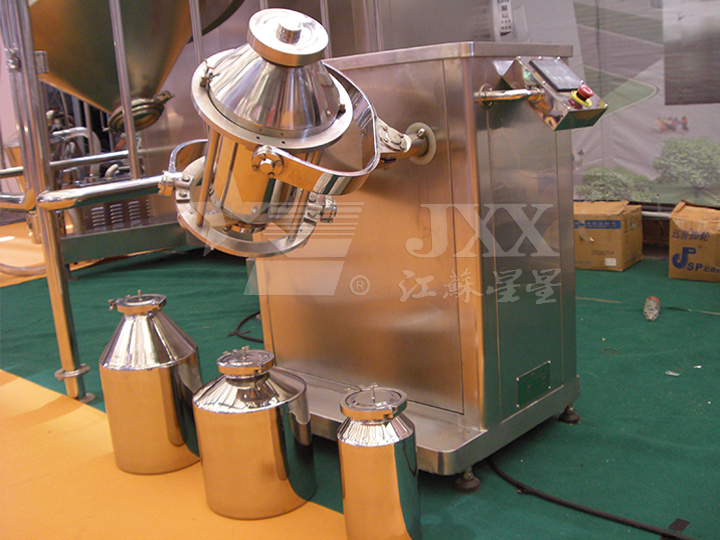

This machine is a high-efficiency mixing equipment that can be used for high uniformity mixing of powdered and granular materials in pharmaceuticals, food, chemical, light industry, machinery, electronics, mining and metallurgy, national defense industry, scientific research enterprises and institutions.

During the mixing process, there is no centrifugal force acting on the material, and there is no specific gravity segregation, layering, or accumulation phenomenon. Each component can be uniformly mixed under vastly different weight ratios, with a mixing rate of over 99.9%.

The loading coefficient is high, reaching up to 80% (compared to only about 40% for ordinary mixers), and the mixing time is short, making it an ideal product among various mixers currently available. The equipment has a compact structure, and the transmission part adopts stepless speed regulation (frequency conversion or electromagnetic speed regulation), which is easy to operate.

Next: None

The future development of spray dryer will develop and improve the spray dryer under the condition of in-depth study of d…

Metal characteristics: The key to the corrosion of hollow blade dryers is that the raw materials of hollow blade dryers a…