Category: Auxiliary equipment

Introduction: 1、 OverviewSingle cone spiral vacuum dryer is a widely used vacuum drying equipment in pharmaceutical production in European and American countries. Manufacturers with years of experience in raw material production know the technical advantages of si…

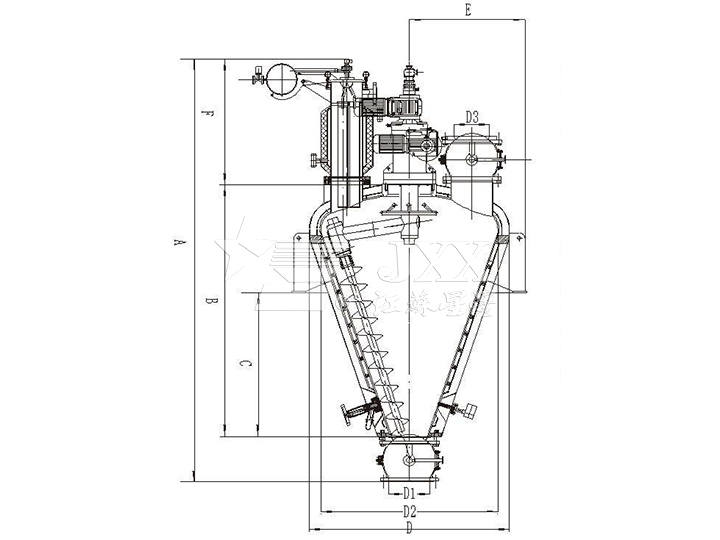

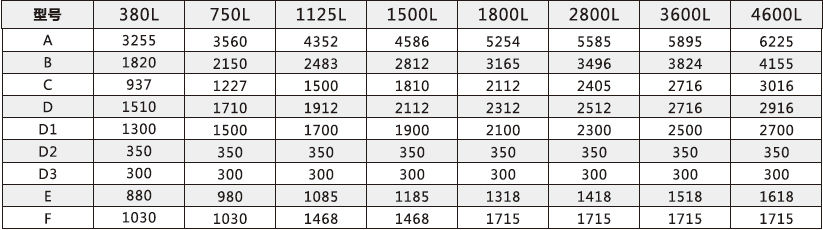

Single cone spiral vacuum dryer is a widely used vacuum drying equipment in pharmaceutical production in European and American countries. Manufacturers with years of experience in raw material production know the technical advantages of single cone spiral vacuum dryer, such as optimized mixing system, heating efficiency of dried materials, high-quality and well manufactured components, precision of zero small distance between spiral mixing and cylinder wall, reliable and sturdy design, and minimal maintenance.

2、 Typical process of vacuum drying mixing

The working process of the single cone spiral vacuum dryer is batch operation. After the wet material enters the silo, it is dried using a jacket, stirring and heating. By selecting a suitable single cone vacuum dryer (working volume), the required processing capacity range can be achieved. The mixer and mixing screw with an upper drive structure can be disassembled and assembled in sections. Due to sufficient installation space, it is suitable for use and maintenance in GMP workshops. At the same time, the single cone spiral vacuum dryer has efficient drying and mixing capabilities, with a material loading rate of 10% - ^ and can work normally. The cantilever screw mixing can achieve high mixing accuracy. Even under harsh conditions such as adding a small amount of material to a large number of materials, it can be mixed evenly in the dryer. With its unique mild mixing characteristics, even products sensitive to drying treatment will not be damaged, and the required driving power is relatively low. The high vacuum design of this dryer has significant advantages for temperature sensitive products, as well as good thermal conductivity, fast drying, and low energy consumption. The filter directly connected to the dryer can retain dust particles in the processing area. The machine adopts an inflatable sealed hemispherical valve for thorough and convenient unloading, excellent vacuum and pressure sealing performance, no dead corners, easy to clean design, stable performance, and long service life, ensuring that you can continue processing products without any loss. This multi-purpose drying/mixing equipment is an excellent tool for meeting your production needs.

3、 Characteristics:

Fully cantilevered conical stirring spiral shaft

Fully enclosed system

The product is gently stirred and has good circulation

Using multiple materials and technologies to achieve safe and reliable sealing

Low mechanical shear force

Short drying time and low energy consumption

High precision, good mixing effect, strong renewability

Gas leakage

Suitable for producing various process products with a wide range of uses

Adjust speed based on product characteristics

Flexible load distribution (10 ^), no impact on product quality

Use a heating and stirring spiral shaft to shorten the drying time

Solid discharge and cleaning solution discharge without residue

Ensure the safety of products, operators, and production processes

Online cleaning is efficient and simple, with thorough emissions

Can be flexibly used for processing various products

Previous: Turnover material bucket

Next: None

The future development of spray dryer will develop and improve the spray dryer under the condition of in-depth study of d…

Metal characteristics: The key to the corrosion of hollow blade dryers is that the raw materials of hollow blade dryers a…