Category: Drying equipment

Introduction: 1、 Working principleIn the traditional horizontal flow box dryer, the airflow only flows on the surface of the material, which has the disadvantages of low heat transfer coefficient, poor heat utilization rate, and long drying time of the material. I…

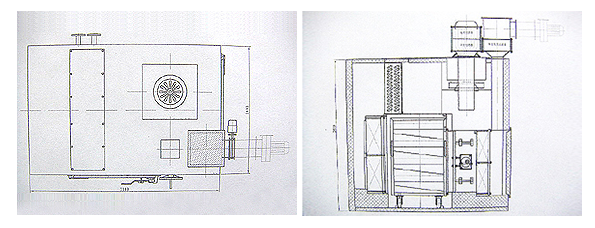

In the traditional horizontal flow box dryer, the airflow only flows on the surface of the material, which has the disadvantages of low heat transfer coefficient, poor heat utilization rate, and long drying time of the material. In order to overcome these disadvantages, our factory has designed and developed a through flow box dryer based on advanced foreign technology. The working principle is shown in the figure:

This machine uses a fan to filter a portion of fresh air through primary, secondary, and tertiary filters, achieving a purification level of 100000. After passing through a steam heat exchanger, the air is heated to a certain temperature, purified by a filter, and then divided into each layer by a left side splitter plate, allowing the hot air to evenly pass through each layer of dried material After the moist air is drawn out from the inclined air duct under the drying tray, a portion of the moist air is discharged from the oven through a centrifugal fan, while the other portion continues to circulate and heat, achieving the purpose of drying.

|

Model specifications |

Drying capacity per time |

Drying capacity per time |

Consumption of steam |

Heating area |

Air volume |

Temperature difference between top and bottom |

Drying tray size |

Number of baking dishes |

Weight |

External dimensions |

|

YCT-C-I |

100 |

4 |

40-80 |

50 |

4000-7300 |

±2 |

550×610×80 |

10 |

2200 |

2350×1400×2280 |

|

YCT-C-II |

200 |

7.5 |

80-120 |

80 |

7200-15800 |

±2 |

530×610×80 |

20 |

4000 |

3100×1600×2700 |

Note: All devices are constantly being improved, and the selection of devices is subject to the new version information.

Previous: GR series hot air circulation oven

The future development of spray dryer will develop and improve the spray dryer under the condition of in-depth study of d…

Metal characteristics: The key to the corrosion of hollow blade dryers is that the raw materials of hollow blade dryers a…