Category: Granulation equipment

Introduction: OverviewThis unit is a device that can simultaneously complete drying and granulation. According to the process requirements, the pressure, flow rate, and nozzle size of the material liquid pump can be adjusted to obtain the required spherical particl…

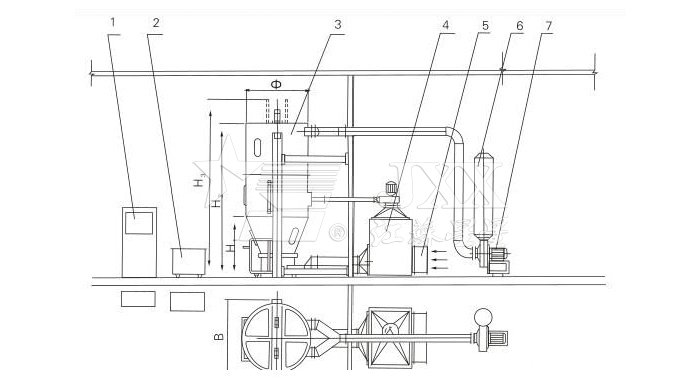

1. Control cabinet 2, infusion trolley 3, host 4, heat exchange cabinet 5, sub high-efficiency filter 6, muffler 7, induced draft fan

| project | Unit/Model | PGL-3B | PGL-5B | PGL-10B | PGL-20B | PGL-30B | PGL-80B | PGL-120B | |

| Unit/Model | min | kg/h | 2 | 4 | 5 | 10 | 20 | 60 | 100 |

| max | kg/h | 4 | 6 | 15 | 30 | 40 | 100 | 140 | |

| Boiling ability | min | kg/批 | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

| max | kg/批 | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

| Liquid specific gravity | kg/L | ≤1.30 | |||||||

|

Quantity of raw material containers |

L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

| Container diameter | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| Induced draft fan power | kw | 3.0 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | |

| Auxiliary fan power | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

| steam |

Consumption |

kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

| pressure | Mpa | 0.40-0.60 | |||||||

|

Electric heating power |

kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

| compressed air | Consumption | m3/min | 0.5 | 0.8 | 0.8 | 0.9 | 1.1 | 1.3 | 1.8 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Operating temperature | °C | Room temperature -160 ° C automatic adjustment | |||||||

| Product moisture | % | ≥0.2 | |||||||

| Material yield | % | ≥99 | |||||||

| Equipment noise | dB | <77 | |||||||

| Host size | Φ | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

| H1 | mm | 940 | 1050 | 1070 | 1220 | 1570 | 1590 | 1690 | |

| H2 | mm | 1900 | 2360 | 2680 | 3150 | 3630 | 4120 | 5050 | |

| H3 | mm | 2050 | 2590 | 3020 | 3600 | 4180 | 4770 | 5800 | |

| B | mm | 740 | 890 | 1110 | 1420 | 1620 | 1820 | 2100 | |

Selection example: It is required that the processing flow extract amount I=120kg (with a solid content of 30%) and seed amount II=60kg in each batch. The theoretical finished product amount M=mI+mII=120kgx30%+60kg=96kg can be obtained from I and II, and the working time T=120kg/30kg/h=4h. The boiling amount can be found in the technical parameter column as the standard load range. Therefore, it is more suitable to choose PGL-30 type for completing two batches per shift.

The future development of spray dryer will develop and improve the spray dryer under the condition of in-depth study of d…

Metal characteristics: The key to the corrosion of hollow blade dryers is that the raw materials of hollow blade dryers a…