Category: Drying equipment

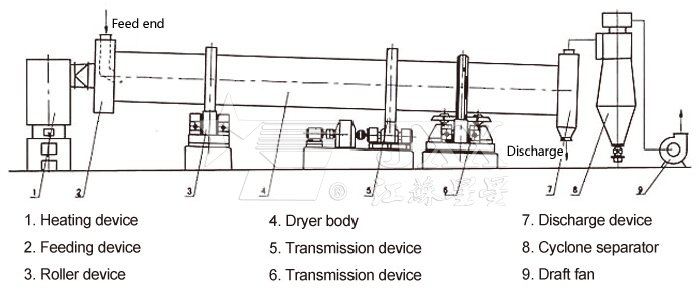

Introduction: Working principleAfter the wet material is put into the dryer at one end, the evenly distributed plate reader inside the inner cylinder flips, and the material is evenly distributed and dispersed within the dryer, fully in contact with the hot air flo…

| model |

Direct heating downstream type |

Direct heating downstream type |

Direct heating countercurrent type |

Direct heating countercurrent type |

Composite heating | Composite heating |

| Material type | ore | HP foaming agent | blast furnace slag | ammonium sulfate | phosphate fertilizer | coal |

|

Processing capacity (kg/h) |

1000 | 466 | 15000 | 20000 | 12000 | 5000 |

|

Water content of discharge (%) |

30 | 13 | 6 | 1.5 | 5 | 6.5 |

|

Final moisture content (%) |

15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

|

Average particle size (mm) |

6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

|

Material stacking density(kg/m3) |

770 | 800 | 1890 | 1100 | 1500 | 750 |

| Hot air volume(kg/h) | 3900 | 5400 | 10750 | 9800 | 6500 | 16000 |

|

Inlet gas temperature(℃) |

600 | 165 | 500 | 180 | 650 | 570 |

|

Material outlet temperature(℃) |

42 | 100 | 70 | 80 | 75 | |

| Heating method | coal gas | Steam electric heating | heavy oil | JRF | heavy oil | heavy oil |

| loading coefficient | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Speed (rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| inclination | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

|

Number of copied boards |

12 | 24 | 12 | 22 |

Inner cylinder outer 8 Inner cylinder outer 16 |

6 12 |

| Drier diameter(m) | 2.0 | 1.5 | 2 | 2.3 |

Outer cylinder 2 Inner cylinder 0.84 |

Outer cylinder 2.4 Inner cylinder 0.95 |

| Dryer length (m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Drive power (kW) | 22 | 7.5 | 15 | 11 | 11 | 15 |

Previous: JYG series hollow blade dryer

The future development of spray dryer will develop and improve the spray dryer under the condition of in-depth study of d…

Metal characteristics: The key to the corrosion of hollow blade dryers is that the raw materials of hollow blade dryers a…