Category: Drying equipment

Introduction: Product IntroductionThe DW series multi-layer belt dryer is a continuous drying equipment used in batch production, used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for materials with high moist…

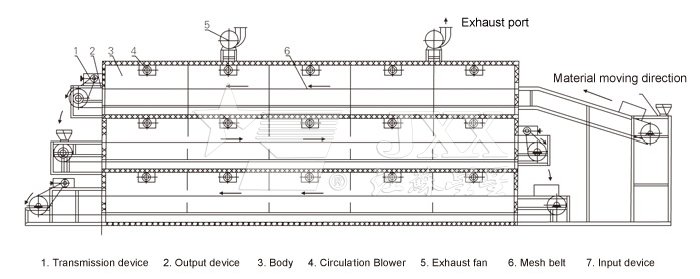

The DW series multi-layer belt dryer is a continuous drying equipment used in batch production, used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for materials with high moisture content such as dehydrated vegetables, catalysts, traditional Chinese medicine slices, and other materials that do not allow high material temperatures; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For paste like materials such as dehydrated filter cakes, they need to be granulated or made into strips before drying.

| model | DW3-1.2-8 | DW3-1.2-10 | DW3-1.6-8 | DW3-1.6-10 | DW3-2-8 | DW3-2-8 |

| Number of units | 4×3 | 5×3 | 4×3 | 5×3 | 4×3 | 5×3 |

| Bandwidth (m) | 1.2 | 1.6 | 2 | |||

| Drying section length (m) | 8×3 | 10×3 | 8×3 | 10×3 | 8×3 | 10×3 |

| Paving thickness (mm) | 10-80 | |||||

| Operating temperature (℃) | 50-140 | |||||

| Steam pressure (Mpa) | 0.2-0.8 | |||||

| Steam consumption (kg/h) | 360-600 | 420-720 | 450-840 | 480-960 | 480-960 | 630-1350 |

| Heat exchange area (m2) | 816 | 1020 | 1056 | 1320 | 1344 | 1680 |

| Drying strength kg water/h | 150-450 | 220-550 | 240-600 | 280-750 | 280-750 | 350-900 |

| Number of fans | 14 | 17 | 14 | 17 | 14 | 17 |

| Total internal power (kW) | 30.8 | 37.4 | 42 | 51 | 56 | 68 |

| Total power of equipment (kW) | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 |

| External dimensions (L × W × H) | 9.77×2.2×4.5 | 11.77×2.2×4.5 | 9.77×2.6×4.7 | 11.77×2.6×4.7 | 9.77×3.06×4.9 | 11.77×3.06×4.9 |

| Total weight kg | 4800×3 | 5780×3 | 5400×3 | 6550×3 | 6350×3 | 7800×3 |

Note: The evaporation amount shown in the figure depends on the drying temperature of the material, the thickness of the material, and the residence time.

Previous: DW single layer belt dryer

The future development of spray dryer will develop and improve the spray dryer under the condition of in-depth study of d…

Metal characteristics: The key to the corrosion of hollow blade dryers is that the raw materials of hollow blade dryers a…